Surface treatment

To achieve ever higher quality of our products, we have invested in a “state of the art” surface treatment system that consists of shot blasting, pre-treatment and powder coating.

Shot blasting

- In order to provide the best possible adhesion of the paint, all of our products are cleand by Shot blasting (automatic) before painting. This rounds sharp edges and removes all of the embers from cutting and welding. At the same time, it ensures an ideal roughness in the surface so that the paint will have optimal adhesion and at the same time have the surface our customers expect

- Maximum size of suspension: 4000mm x 1600mm x 1800mm

Pretreatment

- The pre-treatment for painting is a three-step process with degreasing, iron phosphating and passivation.

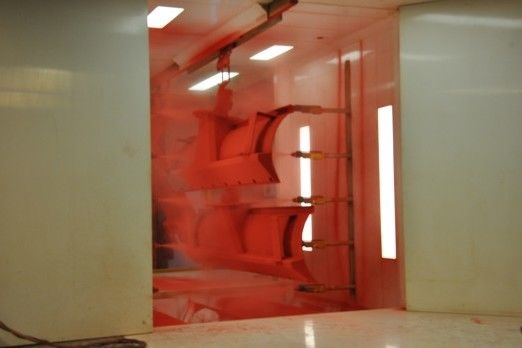

Painting

- Powder coating is applied in a modern powder box with recycling. The products are then run through a curing oven with heating to 200 degrees C before they go to assembly.

- The main amount of paint is applied automatically and the operator performs "control painting" in places that experience has shown poor coverage. Excess powder is collected and reused automatically.

Environmentally friendly surface treatment

- We use a fully circular powder coating box where surplus powder is collected and reused automatically, while no solvents are used in the coating process.

- The pre-treatment is the system fully circular in that an evaporator system has been installed for used process water so that we can reuse this and have no discharge to surface water or municipal network from the paint system. This system also ensured that we supply the pre-treatment plant with filtered stable process water, which in turn ensures the quality of the pre-treatment.